Basics of PLC Modules

A programmable logic computer (PLC) is an industrial digital computer that is generally used to control the process. As it is an industrial computer, a logical program to control the process is prepared in the general computer.

Then this program is transferred to the PLC using cables. This program is stored in the PLC memory.

The logical program is prepared using a programming language called Ladder logic, Statement List, or Functional block diagram. A program is prepared in such a way that the peoples with electrical or instrumentation background can easily understand.

A Programmable Logic Controller consists of various inputs and outputs modules. A PLC monitors the status of switches and sensors using input terminals and based on this status they will give the command to the output devices through the output terminals.

PLC Hardware

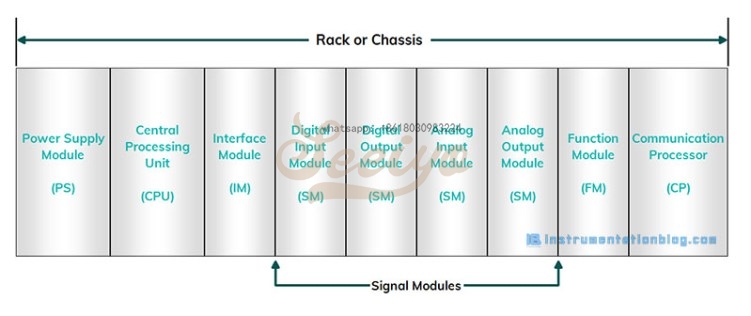

In this article, we are going to see different types of PLC modules. PLC hardware consists of various modules such as,

- Power Supply Module (PS)

- CPU

- Interface Module (IM)

- Signal Modules (SM)

- Function Module (FM)

- Communication Processor (CP)

There are mainly two types of PLCs, generally, we can find in the industry, in terms of hardware

1. Fixed PLC or Compact PLC

All the modules are within a single case. This type of PLC has a fixed number of Input/Output modules.

The power supply, CPU, and communication card are within a single case. From the below image you can get some ideas about the compact or fixed plc.

2. Modular PLC

The name itself suggests that this type of PLC consists of various modules. Inputs and Outputs modules can be easily expanded just by adding the modules.

All the modules are fitted in the rack, that’s why it is also called rack mounted PLC. The below image shows the modular type PLC.

Block Diagram of Siemens PLC Modules

Modular PLCs are the most commonly used PLCs in the industry because it has the reliability to extends the I/Os. There is a rack or chassis in which all the modules are mounted and internally communicated with each other that’s why it is also called “Rack Mounted PLC”.

Rack or Chassis

The rack or chassis is the most important hardware part of the PLC.

The rack or chassis allows all the plc modules to be mounted or connected to a communication bus to communicate with the CPU.

The main functions of the rack or chassis are

- It distributes power evenly

- It houses different input-output modules

- It acts as a link between the CPU and different modules

Power Supply Module (PS)

The power supply module is used to gives the appropriate voltage to a different module as well as the CPU of the PLC system.

The PLC system mostly works with 24V DC voltage, PLC power supply converts line voltage of 100-240 VAC into lower DC voltage generally 24 VDC. PLC power supplies can come in different sizes and ratings based on different plc and applications.

The most common current rating of the power supply module is 5-20 amps for smaller plc systems and it can go up to 50 amps for more complex plc systems.

Central Processing Unit (CPU)

Central Processing Unit, we can say that this is the brain of this system. The program in the form of logical instructions is stored in the CPU.

All the arithmetic and logical functions are performed in the CPU. It executes the instructions as per the stored program by the user.

The Processor in the CPU is used to do computation like managing the computer’s memory, monitoring the status of inputs, and activating output according to the user’s logical instructions.

The Memory in the CPU is used to store programs and data from the different equipment connected to PLC.

Interface Module (IM)

The interface module is used when you want to expand input-output modules and you don’t have space for extra modules in the main rack. You have to connect the other rack with the main rack to communicate it with the CPU.

The interface module is used to connect the other racks with the main rack.

Signal Module (SM)

There are different inputs and outputs are connected with the PLC. These inputs and outputs may be digital or analog.

There are mainly four types of modules are available

- Digital Input Module (DI Module)

- Digital Output Module DO Module

- Analog Input Module (AI Module)

- Analog Output Module (AO Module)

Sometimes, based on the user requirement, a combination of digital input/output and analog input/output modules are also used.

Function Module (FM)

It is an optional module and used with the modular types of PLC. This type of module is generally used with a special type of controlling such as,

- High-Speed Counter Module

- PID Module

- Weighing Module

Communication Processor (CP)

The communication processor module is used mainly for communication with different controllers or devices such as other PLCs, SCADA, HMI, and other controllers.