Difference between Compact PLC and Modular PLC

When I started learning Programmable Logic Controller PLC programming, I found it very difficult to understand the actual difference between compact PLC and modular PLC.

As we all know, the programmable logic controller (PLC) (hardware) has two main categories as follows.

- Compact PLC

- Modular PLC

Now, let’s compare two PLCs.

Difference between Compact PLC and Modular PLC

| # | Content | Compact PLC | Modular PLC |

| 01 | Name | Compact PLC is also known as Fixed PLC. | Modular PLC is also known as Rack-Mounted PLC. |

| 02 | I/O | In Compact PLC, the number of inputs and outputs are fixed. Because I/O capabilities are decided by the manufacturer but not by the user. | In Modular PLC, the number of input and output are not fixed. Inputs and outputs can be added to the modular PLC systems by the user. |

| 03 | Module | It has inputs and outputs modular fitted with CPU. | In this PLC, several components are fitted on chassis or rack or bus with different slots. |

| 04 | Repair | Compact PLC is not easily repaired. | Modular PLC is easy to maintain and repair as compared to compact PLC. |

| 05 | Memory | It has fewer memory capabilities to store data/information. | It has more memory and capabilities to store more data. |

| 06 | Use | It is useful for smaller applications and most suitable for domestic purposes. | It is used for industrial purposes and also for future industrial expansion and growth. |

| 07 | Size | It is smaller in size. | It occurs in a large size with i/o connectivity, power supply, computing capabilities, etc. |

| 08 | Cost | It is an economic model. | It is costlier than Compact PLC. |

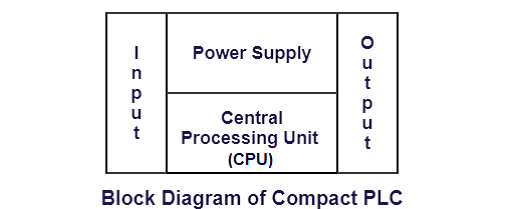

09. Block Diagram

Compact PLC block diagram: It includes input, output along with power supply and CPU.

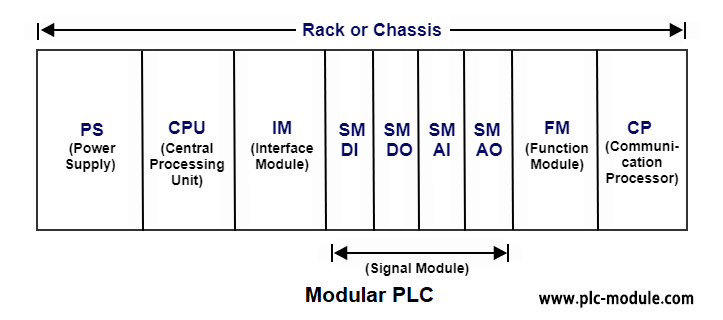

Modular PLC block diagram: It consists of Power Supply, CPU, and Input/Output Modules, Interface Module.

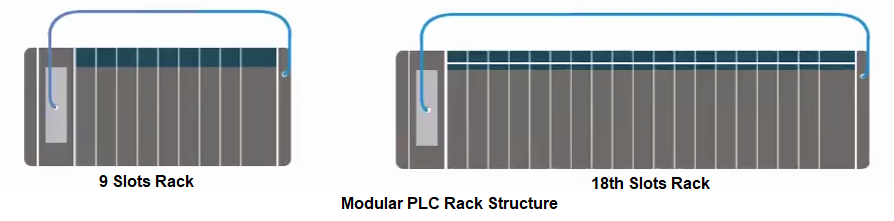

In the modular PLC, one rack consists of nine or eighteen slots.

Out of 9th or 11th slots,

- the power supply connects with the slot number-one,

- the central processing unit (CPU) is fixed in slot number two and

- the interface module is fixed in slot number three.

Remaining slot numbers fourth to eleventh is used for the input and output modules, signal module, a communication module, an interface module, a peripheral module, a function module, etc.

Mostly, modular type PLC is used in automation industries. The more different brands of modular PLC are available in the market with their manufactured brand.

Hopefully, this difference between compact PLC and modular PLC gives you a better understanding. If you have any point to discuss, feel free to write in the comment.

If you are interested in learning PLC programming, here is PLC programming related tutorial from beginner to end.